signed lower right

A forge is both the workplace and hearth of a smith or a blacksmith. The workplace is sometimes referred to as a smithy. The basic smithy contains a forge, also known as a hearth, for heating metals. The forge heats the workpiece to a malleable temperature (a temperature where the metal becomes easier to shape) or to the point where work hardening no longer occurs. The workpiece is transported to and from the forge using tongs. The tongs are also used to hold the workpiece on the smithy's anvil while the smith works it with a hammer. Finally the workpiece is transported to the slack tub, which rapidly cools the workpiece in a large body of water. The slack tub also provides water to control the fire in the forge. A forge typically uses bituminous coal, industrial coke or charcoal as the fuel to heat metal. The designs of these forges have varied over time, but whether the fuel is coal, coke or charcoal the basic design has remained the same.

A forge of this type is essentially a hearth or fireplace designed to allow a fire to be controlled such that metal introduced to the fire may be brought to a malleable state or to bring about other metallurgical effects (hardening, annealing, and drawing temper as examples). The forge fire in this type of forge is controlled in three ways: 1) amount of air, 2) volume of fuel, and 3) shape of the fuel/fire. A forge fire for hot working of metalOver thousands of years of forging, these devices have evolved in one form or another as the essential features of this type of forge:

Tuyere -- a pipe through which air can be forced into the fire

Bellows or blower -- a means for forcing air into the tuyere Firepot or hearth -- a place where the burning fuel can be contained over or against the tuyere opening.

During operation, fuel is placed in or on the hearth and ignited. A source of moving air, such as a fan or bellows, introduces additional air into the fire through the tuyere. With additional air, the fire consumes more fuel and burns hotter.

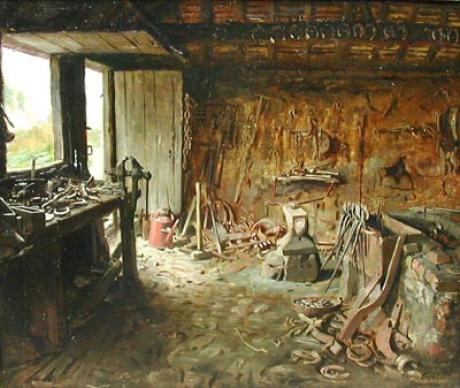

A typical Scottish smithy at Auchentiber, North Ayrshire, Scotland.A blacksmith balances the fuel and air in the fire to suit particular kinds of work. Often this involves adjusting and maintaining the shape of the fire. In a typical, but by no means universal, coal forge, a firepot will be centered in a flat hearth. The tuyere will enter the firepot at the bottom. In operation, the hot core of the fire will be a ball of burning coke in and above the firepot. The heart of the fire will be surrounded by a layer of hot but not burning coke. Around the unburnt coke will be a transitional layer of coal being transformed into coke by the heat of the fire. Surrounding all is a ring or horseshoe-shaped layer of raw coal, usually kept damp and tightly packed to maintain the shape of the fire's heart and to keep the coal from burning directly so that it "cooks" into coke first. If a larger fire is necessary, the smith increases the air flowing into the fire as well as feeding and deepening the coke heart. The smith can also adjust the length and width of the fire in such a forge to accommodate different shapes of work. The major variation from the forge and fire just described is a 'back draft' where there is no fire pot, and the tuyere enters the hearth horizontally from the back wall. Coke and charcoal may be burned in the same forges that use coal, but since there is no need to convert the raw fuel at the heart of the fire (as with coal), the fire is handled differently. Individual smiths and specialized applications have fostered development of a variety of forges of this type, from the coal forge described above, to simpler constructions amounting to a hole in the ground with a pipe leading into it.

Anvil

The anvil serves as a work bench to the blacksmith, where the metal to be beaten is placed. Anvils are made of cast or wrought iron with a tool steel face welded on or of a single piece of cast or forged tool steel. The flat top has two holes; the wider is called the hardy hole, where the square shank of the hardy fits. The smaller hole is called the punch hole, used as clearance when punching holes in hot metal.

Chisel

Chisels are made of high carbon steel. They are hardened and tempered at the cutting edge while the head is left soft so it will not crack when hammered. Chisels are of two types, hot and cold chisels. The cold chisel is used for cutting cold metals while the hot chisel is for hot metals. Usually hot chisels are thinner and therefore can not be substituted with cold chis.

Tongs

Tongs are used by the blacksmith for holding hot metals securely. The mouths are custom made by the smith in various shapes to suit the gripping of various shapes of met.

Fuller

Fullers are forming tools of different shapes used in making grooves or hollows. They are often used in pairs, the bottom fuller has a square shank which fits into the hardy hole in the anvil while the top fuller has a handle. The work is placed on the bottom fuller and the top is placed on the work and struck with a hammer. The top fuller is also used for finishing round corners and for stretching or spreading metal.

Hardy

The hardy is a cutting tool similar to the chisel. It is used as a chisel or hammer for cutting both hot and cold metals. It has a square shank that fits into the hardy hole in the anvil, with the cutting edge facing upwards. The metal to be cut is placed on the cutting edge and struck with a hammer. They are also used with set tools which are placed over the workpiece and struck.

Slack tub

A slack tub is usually a large container full of water, brine, or oil used by a blacksmith to quench hot metal. The term is believed to derive from the word "slake", as in slaking the heat.